Shear Studs

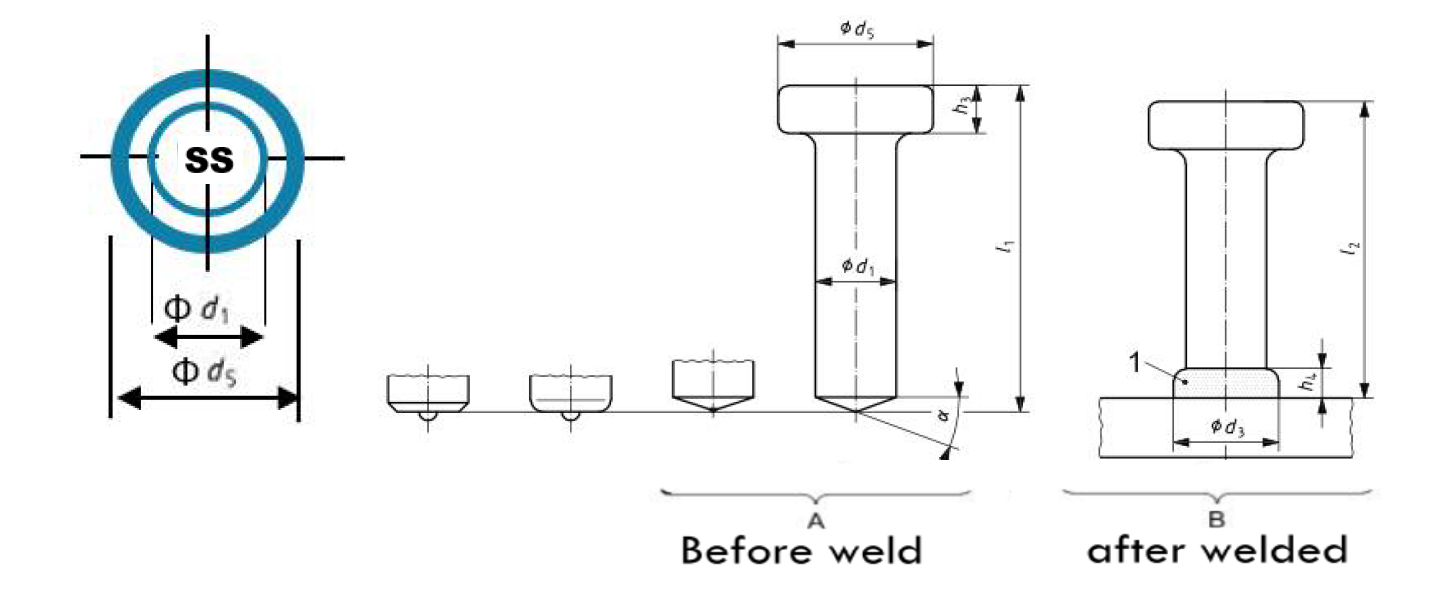

The functionality of shear stud is to give a structural connection between the concrete block and the structural steel. Generally the shear studs will be welded, with a spot welder (known as ferrule), after the metal deck is installed over the supporting structural steel. The spot welder will burn through the metal deck and attach the shear stud directly to the top of the steel beam. Arc Welding Shear stud connector and metal deck welding application diagram. Our “SS” Shanghai Shangluo 上海上螺 Arc Welding Shear Stud Connector manufactured accordance to EN ISO 13918 and BS 5400 standard by FPC Certified factory. The Shear stud connector are designed to tie the concrete slab to steel beam and resist shear loadings between the concrete slab and steel beam in composite construction.

Shear stud configuration design rules

The values used by the steel designer for shear stud strength rely on a concrete ‘cone of failure’ around the stud (see photo below) and the studs being spaced to the design rules stated. There are a number of rules and recommendations from approved design standards and industry best practice which specify spacings, dimensions and layout of studs in order to achieve the required stud resistance. Below is a selection of the most common examples.